Description

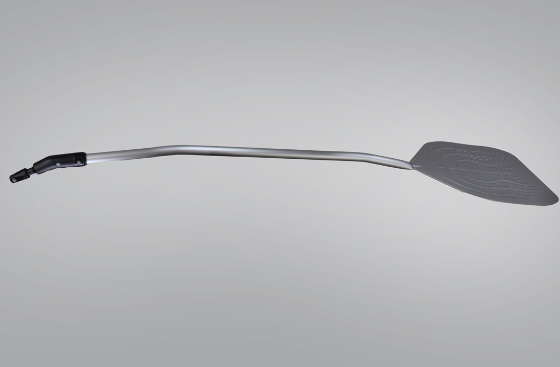

The high-quality aluminum alloy provides excellent resistance to corrosion, heat, and mechanical stress while maintaining a reasonable light weight. The 2 mm thickness of the sheet metal provides greater strength and stability to the product.

Medium-thickness anodizing

The anodizing process increases the aluminum alloy’s corrosion resistance, wear and abrasion resistance, and heat resistance. These improvements depend on the thickness of the protective oxide layer.

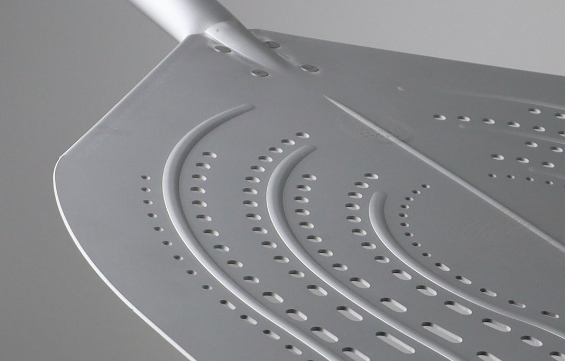

The perforations on the peel plate reduce the weight of the peel and allow excess flour to drain away, which would otherwise burn during baking and, in addition to being unhealthy, also taste unpleasant.

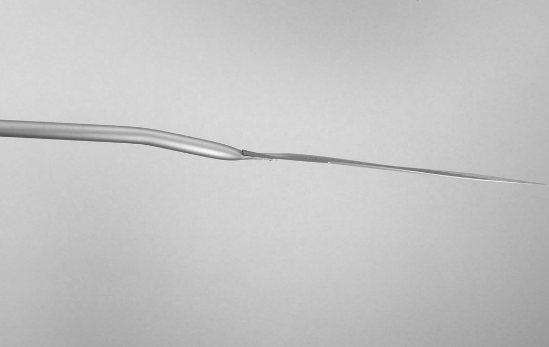

Milled tip

The milling makes it easier for the pizza to slide onto the peel plate.

The micro-dotted finish on the tip of the peel creates a smoother transition between the peel plate and the pizza, thanks to the action of the flour “captured” by these micro-holes.

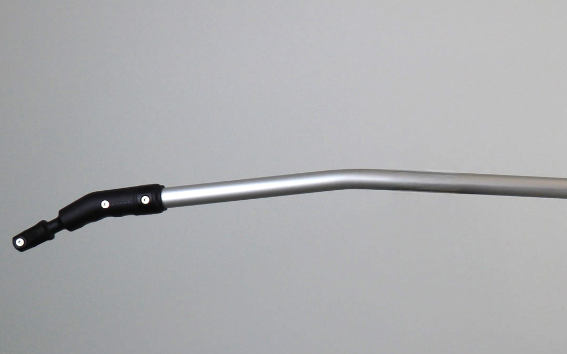

The aluminum alloy joining insert on the peel plate is inserted and secured to the peel inside the tube. This increases its bending resistance and acts as a thermal joint, limiting heat diffusion to the blade tube.

The flattened rivets join the parts together for a solid, durable, and long-lasting connection.

The plastic end cap is attached to the handle with a snap-fit mechanism. The hole in the handle allows the product to be hung on any hook. In the event of breakage, replacement is recommended, and a spare part is available.